Globe

GLOBE

Complete Processing of Optical components

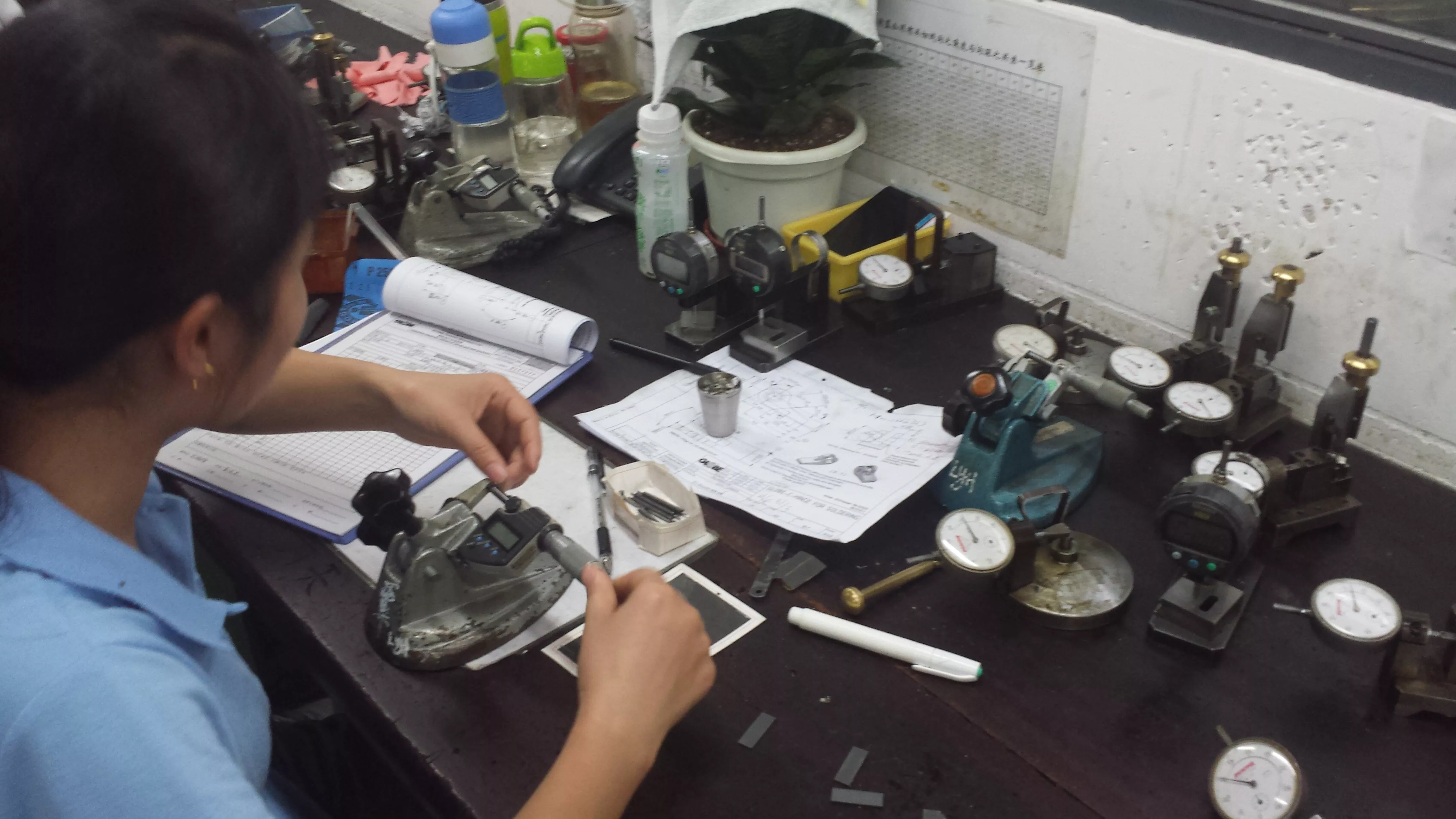

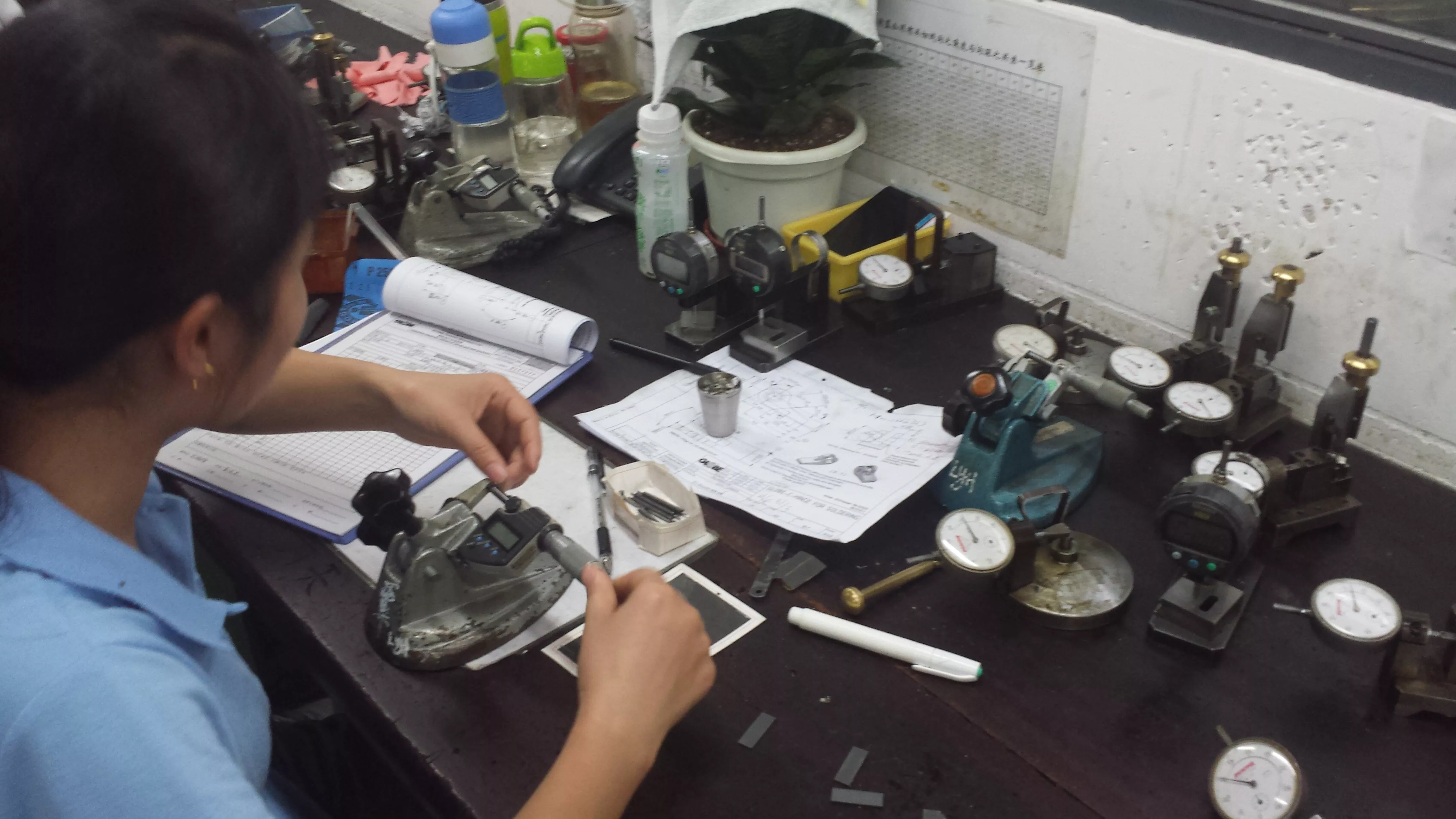

The eyewear component company GLOBE Precision Ltd. with its factory in Shenzhen and office in Hong Kong is a 100% owned company of OBE GmbH & Co. KG, Germany, world-wide leader in the market of components for eyewear frames. Since its foundation in 2004 GLOBE is expanding constantly and producing in the plant in Shenzhen with the latest manufacturing processes. The high quality standards have been documented in 2009 with the certification DIN EN ISO 9001. In 2017 GLOBE has established an environmental management system and has been certified according to DIN EN ISO 14001.

GLOBE

Complete Processing of Optical components

The eyewear component company GLOBE Precision Ltd. with its factory in Shenzhen and office in Hong Kong is a 100% owned company of OBE GmbH & Co. KG, Germany, world-wide leader in the market of components for eyewear frames. Since its foundation in 2004 GLOBE is expanding constantly and producing in the plant in Shenzhen with the latest manufacturing processes. The high quality standards have been documented in 2009 with the certification DIN EN ISO 9001. In 2017 GLOBE has established an environmental management system and has been certified according to DIN EN ISO 14001.

Customised solutions

In addition to a standard program of different hinge types for metal, plastic and combination frames GLOBE is specialized for customer specific solutions as well as processing services. In any case customers receive the maximum attention and a competent consulting service. Thanks to continuous investments GLOBE has become over the years a key supplier of components for the Asian eyewear industry.

Safety system

GLOBE hinges can generally be combined with OBE’s “Space Screws” fastener security system. This system, which essentially functions as a tolerance compensation mechanism, ensures a smooth hinge motion while maintaining secure screw retention.

Globe

What sets us apart

GLOBE

Our technologies

Machining

Shaping & Forming

Joining Techniques

Surface treatment

Machining

Shaping & Forming

Joining Techniques

Surface treatment

GLOBE

Our product portfolio

We offer a wide range of hinges for the eyewear industry and can provide solutions for virtually any frame type. From acetate frames to metal and titanium designs, our components integrate perfectly into every eyewear model. We even supply suitable solutions for smart glasses.

In addition to our standard products, our key strength lies in developing custom hinges tailored to our customers’ needs. We specialiae particularly in personaliaed wiresfor transparent acetate frames.

Globe

Gallery